Featured products

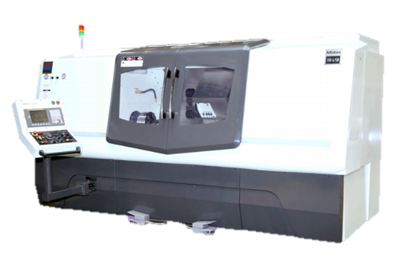

Midas 0

The Midas 0 CNC Chucker has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life .

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High spindle speed 6000 rpm

- Slant Bed for efficient chip disposal

- 8 Station Tool Turret

- Tail Stock

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

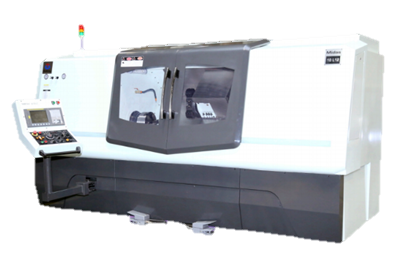

Midas 0g

The Midas 0g CNC Chucker has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life .

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High spindle speed 6000 rpm

- Slant Bed for efficient chip disposal

- Linear Tooling ( Quicker Tool Change & Higher Accuracy )

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

Midas 4i

The Midas 4i CNC Universal Turning Center has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life .

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High spindle speed 6000 rpm

- Slant Bed for efficient chip disposal

- 8 Station Tool Turret

- Tail Stock

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

Midas 4GG

The Midas 4GG CNC Double Spindle Chucker is perfectly suited for 2- set up operations on symmetrical work - pieces . It has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results:- optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life.

Key Features :-

- Perfectly suited for adapting to Automation Solutions

- Highest rapid traverse 30 m/min for X and Z axes

- High spindle speed 4000 / 6000 rpm ( Optional )

- Slant Bed for efficient chip disposal

- Linear Tool Slide

- Double Spindle ( opposed )

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

Midas 6

The Midas 6 CNC Universal Turning Center is the perfect work horse for Job Shop applications. It has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life.

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High spindle speed 4000 / 6000 rpm ( Optional )

- Slant Bed for efficient chip disposal

- 8 Station Tool Turret

- Tail Stock

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

Midas 6 Plus

The Midas 6 plus CNC Universal Turning Center is the perfect work horse for Job Shop applications . It has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life .

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High spindle speed 4000 / 6000 rpm ( Optional )

- Slant Bed for efficient chip disposal

- 8 Station Hydraulic Tool Turret

- Tail Stock

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

Midas 8i

The Midas 8i CNC Universal Turning Center is the perfect work horse for Job Shop applications. It has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life.

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High spindle speed 4000 / 6000 rpm ( Optional )

- Slant Bed for efficient chip disposal

- 8 Station Hydraulic Tool Turret

- Tail Stock

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

Midas 10

The Midas 10 CNC Universal Turning Center is a heavy duty lathe for precision machining of medium to large work pieces.

It has a very compact structure offering optimum use of available space in the workshop. The sturdy and the robust components such as the main bed, linear rails and spindle combined with powerful spindle motor allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life .

Key Features :-

- Highest rapid traverse 40 m/min for X and Z axes

- High torque spindle speed 3000 / 6000 rpm ( Optional )

- Slant Bed for efficient chip disposal

- 8 Station Tool Turret

- Tail Stock

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Compact and highly reliable interface hardware cabinet

- Homing less axes operations using absolute encoders feed back

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

- Perfectly suited for adapting to Automation Solutions

Midas 10L3

The Midas 10(L3/L6/L9/L12) is a Heavy-Duty Turning Center with rugged base & following convenient features :-

Key Features :-

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- High rapid traverse 30 m/min for X and Z axes

- Available in variants ( L3 / L6/ L9 / L12 ) for adapting to different job lengths

- A-2- 8 Spindle available as option ( larger Bearings and Spindle Bore )

- Roller Steady Rest available for shaft applications

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Homing less axes operations using absolute encoders feed back

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

Midas 10L6

The Midas 10(L3/L6/L9/L12) is a Heavy-Duty Turning Center with rugged base & following convenient features :-

Key Features :-

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- High rapid traverse 30 m/min for X and Z axes

- Available in variants ( L3 / L6/ L9 / L12 ) for adapting to different job lengths

- A-2- 8 Spindle available as option ( larger Bearings and Spindle Bore )

- Roller Steady Rest available for shaft applications

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Homing less axes operations using absolute encoders feed back

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

Midas 6TGM-TGM

MIDAS 6GG Series is a Unique Machine from GALAXY Range , based on the innovative concept of “Build- Your – Own – Machine!”

The Modular Machine Layout allows a user to choose from a wide variety of Tooling Layout Options so as to design a machine specific to his unique needs!

You can create your own combination of Linear Tooling slides and / or Tool Turrets , and choose from the following Options of Machine Configuration :-

| POSSIBLE TOOL COMBINATIONS ON BOTH SLIDES | |||||

| 6G-G | 6T-T | ||||

| 6GM-G | 6TG-G | 6GM-G | 6TG-G | 6GGM-G | 6TGM-G |

| 6GM-T | 6TG-T | 6GM-T | 6TG-T | 6GGM-T | 6TGM-T |

| 6GM-GM | 6TG-GM | 6GM-GM | 6TG-GM | 6GGM-GM | 6TGM-GM |

| 6GM-TG | 6TG-TG | 6GM-TG | 6TG-TG | 6GGM-TG | 6TGM-TG |

| 6GM-GGM | 6TG-GGM | 6GM-GGM | 6TG-GGM | 6GGM-GGM | 6TGM-GGM |

| 6GM-TGM | 6TG-TGM | 6GM-TGM | 6TG-TGM | 6GGM-TGM | 6TGM-TGM |

ABBREVIATIONS:-

G : GANG TOOLING

T : TURRET TOOLING

M : MILLING ( LIVE TOOL OPTION )

Midas 10L12

The Midas 10(L3/L6/L9/L12) is a Heavy-Duty Turning Center with rugged base & following convenient features :-

Key Features :-

- High Precision ball screws for X & Z axes

- Precision Linear motion guides for X and Z axes

- High rapid traverse 30 m/min for X and Z axes

- Available in variants ( L3 / L6/ L9 / L12 ) for adapting to different job lengths

- A-2- 8 Spindle available as option ( larger Bearings and Spindle Bore )

- Roller Steady Rest available for shaft applications

- Lowest foot print area by compact layout of machine elements

- Access doors to machine elements for easy maintenance

- Optional hydraulic spindle brake for easy chuck/jaw removal

- Separated Lube oil collection to prevent coolant contamination

- Powerful interface software for machine functions with high safety

- Homing less axes operations using absolute encoders feed back

- Ergonomically designed operator panel

- Optional chucking systems, chip conveyor

Heracles 20

The Optimally Designed Machine Structure gives the Heracles 20 the ultimate rigidity and stability. All

structural parts are precisely machined on the sophisticated precision machines to achieve the highest

geometrical accuracies. Then they are delivered to the machine manufacturing line for assembly with

meticulous care by highly skilled technicians. At each step throughout the entire manufacturing process,

each technician is always dedicated to pursue quality excellence with meticulous attitude.

Heracles 20 Sonic

The Optimally Designed Machine Structure gives the Heracles 20 Sonic the ultimate rigidity and stability.

All structural parts are precisely machined on the sophisticated precision machines to achieve the

highest geometrical accuracies. Then they are delivered to the machine manufacturing line for assembly

with meticulous care by highly skilled technicians. At each step throughout the entire manufacturing

process, each technician is always dedicated to pursue quality excellence with meticulous attitude.

Heracles 24

The Optimally Designed Machine Structure gives the Heracles 24 the ultimate rigidity and stability. All structural parts are precisely machined on the sophisticated precision machines to achieve the highest geometrical accuracies. Then they are delivered to the machine manufacturing line for assembly with meticulous care by highly skilled technicians. At each step throughout the entire manufacturing process, each technician is always dedicated to pursue quality excellence with meticulous attitude.

STANDARD FEATURES :-

- Precision Linear Motion Guides for X,Y and Z Axes

- Rigid Tapping

- Spindle Air Blast

- Pre-Tensioned Ball Screws for all axes

- Panel Cooler for Electrical Cabinet

- Fully Enclosed Splash Guards

- Pneumatic System

- Spindle Oil Cooler

- Coolant Through Spindle

- Auto Tool Length Measurement

- Work Piece Measurement

- Linear Scales

- High Pressure Coolant Pump

- 4th and 5th Axes Rotary Table Unit

Heracles 24 FM

The Optimally Designed Machine Structure gives the Heracles 24 FM the ultimate rigidity and stability. All the pre-manufacturing design analysis was undertaken to optimize machine structure design with greater stability of structural assembly quality and to upgrade cutting performance by means of dynamic rigidity test and spectrum analysis for vibration, so that we can fully meet customers' requirements for high machining efficiency with greater accuracy. It has following features

STANDARD FEATURES :-

- Precision Linear Motion Guides for X,Y and Z Axes

- Rigid Tapping

- Spindle Air Blast

- Pre-Tensioned Ball Screws for all axes

- Panel Cooler for Electrical Cabinet

- Fully Enclosed Splash Guards

- Pneumatic System

- Spindle Oil Cooler

- Coolant Through Spindle

- Auto Tool Length Measurement

- Work Piece Measurement

- Linear Scales

- High Pressure Coolant Pump

- 4th and 5th Axes Rotary Table Unit

Heracles 24 PC

The Optimally Designed Machine Structure gives the Heracles 24 PC the ultimate rigidity and stability. All the pre-manufacturing design analysis was undertaken to optimize machine structure design with greater stability of structural assembly quality and to upgrade cutting performance by means of dynamic rigidity test and spectrum analysis for vibration, so that we can fully meet customers' requirements for high machining efficiency with greater accuracy. It has following features

STANDARD FEATURES :-

- Precision Linear Motion Guides for X,Y and Z Axes

- Rigid Tapping

- Spindle Air Blast

- Pre-Tensioned Ball Screws for all axes

- Panel Cooler for Electrical Cabinet

- Fully Enclosed Splash Guards

- Pneumatic System

- Spindle Oil Cooler

- Coolant Through Spindle

- Auto Tool Length Measurement

- Work Piece Measurement

- Linear Scales

- High Pressure Coolant Pump

- 4th and 5th Axes Rotary Table Unit

Heracles 33

The Optimally Designed Machine Structure gives the Heracles 33 the ultimate rigidity and stability. All structural parts are precisely machined on the sophisticated precision machines to achieve the highest geometrical accuracies. Then they are delivered to the machine manufacturing line for assembly with meticulous care by highly skilled technicians. At each step throughout the entire manufacturing process, each technician is always dedicated to pursue quality excellence with meticulous attitude. All the pre-manufacturing design analysis was undertaken to optimize machine structure design with greater stability of structural assembly quality and to upgrade cutting performance by means of dynamic rigidity test and spectrum analysis for vibration, so that we can fully meet customers' requirements for high machining efficiency with greater accuracy. It has following features

STANDARD FEATURES :-

- Precision Linear Motion Guides for X,Y and Z Axes

- Rigid Tapping

- Spindle Air Blast

- Pre-Tensioned Ball Screws for all axes

- Panel Cooler for Electrical Cabinet

- Fully Enclosed Splash Guards

- Pneumatic System

- Spindle Oil Cooler

- Coolant Through Spindle

- Auto Tool Length Measurement

- Work Piece Measurement

- Linear Scales

- High Pressure Coolant Pump

- 4th and 5th Axes Rotary Table Unit

Heracles 33 FM

The Optimally Designed Machine Structure gives the Heracles 33 FM the ultimate rigidity and

stability. All the pre-manufacturing design analysis was undertaken to optimize machine structure design with greater stability of structural assembly quality and to upgrade cutting performance by means of dynamic rigidity test and spectrum analysis for vibration, so that we can fully meet customers' requirements for high machining efficiency with greater accuracy. It has following features

STANDARD FEATURES :-

- Precision Linear Motion Guides for X,Y and Z Axes

- Rigid Tapping

- Spindle Air Blast

- Pre-Tensioned Ball Screws for all axes

- Panel Cooler for Electrical Cabinet

- Fully Enclosed Splash Guards

- Pneumatic System

- Spindle Oil Cooler

- Coolant Through Spindle

- Auto Tool Length Measurement

- Work Piece Measurement

- Linear Scales

- High Pressure Coolant Pump

- 4th and 5th Axes Rotary Table Unit

Heracles 33 PC

The Optimally Designed Machine Structure gives the Heracles 33 PC the ultimate rigidity and stability. All the pre-manufacturing design analysis was undertaken to optimize machine structure design with greater stability of structural assembly quality and to upgrade cutting performance by means of dynamic rigidity test and spectrum analysis for vibration, so that we can fully meet customers' requirements for high machining efficiency with greater accuracy. It has following features

STANDARD FEATURES :-

- Precision Linear Motion Guides for X,Y and Z Axes

- Rigid Tapping

- Spindle Air Blast

- Pre-Tensioned Ball Screws for all axes

- Panel Cooler for Electrical Cabinet

- Fully Enclosed Splash Guards

- Pneumatic System

- Spindle Oil Cooler

- Coolant Through Spindle

- Auto Tool Length Measurement

- Work Piece Measurement

- Linear Scales

- High Pressure Coolant Pump

- 4th and 5th Axes Rotary Table Unit

K'MX 413

K’MX 413 is dedicated to run small parts from Ø 2–16 mm (over Ø 13 mm a preparation of bars is necessary in standard, as option can be used full Ø 16 mm bar without preparation). Designed as an all package, the K’MX 413 is standardized and ready to produce. Sub spindle, powered tools are included in the basic machine as well as the bar loader. The light kinematic and FANUC 0i controller provides an easy and quick programming reducing the setup time. With 2 electro spindles, 3 powered tools, C-axis, and up to 12 fixed tools, the K’MX 413 is also able to run sophisticated parts. With this machine, GALAXY-TAJMAC Machinery wants to offer an economical, reliable and easy solution.

K'MX 432,632

Sliding headstock (Swiss type) automatic lathe K'MX 432, 632 is designed for productive machining of parts from the bars of maximum diameter 32 mm. As the spindle bore diameter is 37 mm, there is no modification of the end of the bar for bar feeder collet needed.

Machine is equipped in standard with two electro spindles with maximum speed 10.000 rpm each and with rotary guide bush synchronized by pulleys and belts with main spindle. Four linear axes (X1, Y1, Z1, aZ2); two rotary axes (C1, C2) enable to machine with high productivity the simple as well as complex parts. K‘MX 432, 632 is the ideal solution to manufacture parts with high productivity.

K'MX 532 TREND

Sliding headstock (Swiss type) automatic lathe MANURHIN K’MX 532 TREND is designed for productive machining of parts from the bars of maximal diameter 32 mm. As the spindle bore diameter is 37 mm, there is no modification of the end of the bar for bar feeder collet needed.

Machine is equipped in standard with two electro spindles with maximum speed 10.000 rpm each and with rotary guide bush synchronized by pulleys and belts with main spindle. Five linear axes (X1, Y1, Y2, Z1, and Z2) two rotary axes (C1, C2) enable to machine with high productivity the simple as well as complex parts.

K'MX 632 DUO

Sliding headstock (Swiss type) automatic lathe MANURHIN K’MX 632 DUO is designed for productive machining of parts from the bars of maximal diameter 32 mm. As the spindle bore diameter is 37 mm, there is no modification of the end of the bar for bar feeder collet needed. Machine is equipped in standard with two electro spindles with maximum speed 10.000 rpm each and with rotary guide bush synchronized by pulleys and belts with main spindle. Six linear CNC axes (X1, X2, Y1, Y2, Z1, and Z2) two rotary axes (C1, C2) enable to machine with high productivity the simple as well as complex parts. Big advantage of this model is possibility of parallel turning or milling with two tools in one time.

K'MX 732 EVO

Sliding headstock (Swiss type) automatic lathe MANURHIN K’MX 732 EVO is designed for productive machining of parts from the bars of maximal diameter 32 mm. As the spindle bore diameter is 37 mm, there is no modification of the end of the bar for bar feeder collet needed. Machine is equipped in standard with two electro spindles with maximum speed 10.000 rpm each and with rotary guide bush synchronized by pulleys and belts with main spindle. Seven linear CNC axes (X1, X2, Y1, Y2, Z1, Z2, and W1) two rotary axes (C1, C2) enable to machine with high productivity the simple as well as complex parts. Construction solution enables of use up to 4 tools at the same time.

K'MX 816 CLEVER

Sliding headstock (Swiss type) automatic lathe MANURHIN K’MX 816 CLEVER is designed for productive machining of parts from the bars of maximal diameter 16 or 20mm. Machine is equipped in standard with two electro spindles and with rotary guide bush synchronized by pulleys and belts with main spindle. Eight linear CNC axes and two rotary axes enable to machine with high productivity the simple as well as complex parts. Construction solution enables the use of 4 tools at the same time.

K'MX SWING

The K’MX SWING 10 AXIS is dedicated to machining complex parts from the bar up to o 32 mm. The SWING 10 AXIS is delivered in two versions – for bars Ø 26 and Ø 32 mm. The main characteristics from K’MX SWING 10 AXIS are: Productivity, up to 23 tools including 14 powered tools, up to 4 tools, working simultaneously with 10 independent axes. An easy and quick tool change with the compatible tool holder cartridge system. A simplified programming with K’MX PLUS software, Ergonomic and easy access with large opening door and a numerical control working under, WINDOWS.

K’MX SWING is the ideal solution to manufacture complex parts with high productivity and useful for the operator.

Biglia B436 - Y2

The range of QUATTRO machines have been produced by Biglia since 1990 and celebrating the third generation is now further enhanced by the B436Y2 model. This new model is launched to meet with the specific market requirements for bar machining in automatic turning: a twin-turret and twin-spindle CNC-lathe with fixed headstock, compact, versatile and quick for combined turning, milling and drilling of small-sized parts. The B436Y2 has a very compact structure offering optimum use of available space in the workshop (less than 5 sqm). The sturdy cast-iron construction, the robust components such as the main bed, linear rails, turrets and spindles combined with powerful spindle motors (11 kW) and live tools (max. 4.6 kW) will allow you to achieve significant results: - optimal machining of all materials, especially tough alloys - reduction of cycle times and longer tool service life - perfect and efficient method of ‘Chip’ removal - ergonomics and easy access for setup and retooling operations.

Biglia B446 - T2 B465

20 years after the launch of the first QUATTRO machine, this range of double-spindle and double-turret turning centers for bar machining celebrating the third generation is now further enhanced by the new range of QUATTRO Y2: the latest evolution of the established B445/B470Y series.

The main performance benefits offered by the 30-degree slant bed and the robust machine components such as the structure, guides and turrets are:

- Great rigidity allowing to machine tough materials

- Perfect removal of chippings

- Reduction of cycle times and longer tool service life

- Up to 30 tools available for machining of complex parts and reduced set-up times

- Ergonomics and easy access for retooling operations.

The modular design allows a wide range of customized configurations to be offered, resulting in extremely efficient and flexible production of simple to complex parts using live tools, C-axis and Y-axis. The QUATTRO Y2 turning centers are available in three configurations featuring 45 and 65 mm bar capacity.

Biglia B545 - B565

The new B545 / 565 models are the latest evolution of the established B510 series.

BIGLIA now offers a range of high quality universal lathes that, thanks to the sturdy bed and the new BIGLIA turret, deliver:

• THE NECESSARY RIGIDITY

• ACCURACY

• RAPIDITY IN MACHINING

all of this combined with

• GREAT RELIABILITY

• VERY COMPETITIVE PRICES.

The modular concept enables a wide range of alternative specifications and functions, from simple turning to complete machining using live tools, sub-spindle and C/Y axis.

The new B545 / B565 models are available in 6 versions with bar capacity of 45 mm or 65 mm allowing to meet your every requirement in every application.

Biglia B750

The new B750/B1250 series represents the “state of the art” of multifunction turning centers.

The new turret with direct drive built-in motor is the heart of this range of machines.

Available in 10 versions featuring 750 mm or 1250 mm turning length, this line of machines provides a wide spectrum of machining possibilities ranging from universal turning to complete machining of complex parts thanks to the CNC automatic tailstock,

sub-spindle, rotary tools and C/Y axis.

More accuracy Delivered by the rugged bed designed for higher heat stability, and the thermal stabilization of the main heat sources such as spindles, turret and hydraulic unit.

More productivity

Thanks to the massive rigid cast-iron machine bed and the flat hardened and ground slide-ways on all axes ensuring high rigidity and exceptional vibration dampening.

The fast indexing, sturdy BIGLIA servo-turret, and the high capability of chip removal in both turn and mill operations are enabled by the new powerful servo motors.